艾捷博雅磁性固相萃取技术亮相ASMS 2024美国质谱学会年度会议暨展览会

2024-06-27 13:06:09 苏州艾捷博雅科技有限公司

Introduction

引言

The conventional column and plate solid-phase extraction (SPE) format encounter various unresolved issues, such as inconsistent flow rates, column clogging from protein precipitation, and packing bed channeling due to polymer SPE materials swelling and shrinking with solvent changes.

传统的固相萃取(SPE)如柱式和板式,存在各种未解决的问题。如流速不一致、SPE柱因蛋白质沉淀而堵塞,以及聚合物SPE材料在溶剂变化时由于膨胀和收缩而产生“沟渠效应”。

A promising alternative, moving bed SPE employing mesoporous paramagnetic sorbents, has superseded traditional column SPE methods, facilitating complete automation of the extraction process. Rather than passing samples through a static SPE column or packed bed, the innovative SPE techniques involve moving sorbents, which have adsorbed analytes, from samples to one or more vessels containing rinsing solvents. Subsequently, the sorbents are transferred from the rinsing vessels to the elution vessel, where analytes are eluted from the sorbent into the solution.

一种有前景的替代方案——使用介孔顺磁吸附剂的移动床固相萃取,已经取代了传统的柱式固相萃取方法,实现了萃取过程的完全自动化。不同于将样品通过静态SPE柱或填料床,这种新型SPE技术包括:首先将已吸附分析物的吸附剂从样品转移到一个或多个含有冲洗溶剂的容器中;随后,吸附剂从冲洗容器转移到洗脱容器,将分析物从吸附剂洗脱到溶液中。

Figure 1. Workflow of moving-bed extraction by m-SPE

图1. m-SPE移动床萃取工作流程

Figure 2. Auto M32 m-SPE pretreatment system

图2. Auto M32磁固相萃取前处理系统

Technical Approach and Highlights

技术方案及亮点

The magnetic separation material comprises a magnetic core encased in a silicone or polymer shell with controlled apertures ranging from 80 to 100Å, achieved through specialized control techniques. This design leverages a physical size exclusion effect where the pores facilitate the entry of small molecules while restricting larger molecular interference substances. This strategy effectively mitigates the matrix effect and fulfills the objectives of purification, enrichment, and detection.

磁分离材料包括一个磁核,其外表包覆有硅胶或聚合物壳,并通过特殊技术将孔径控制在80~100Å之间。这种设计利用了物理尺寸排除效应,孔隙有助于小分子进入,同时限制较大的分子干扰物质。这种方法有效地减轻了基质效应,并实现了纯化、富集和检测的目标。

Figure 3. Process of magnetic beads production

图3. 磁珠生产过程

The magnetic core packaging process is crucial to prevent oxidation and demagnetization. Ensuring uniform mesoporous apertures and a high specific surface area are essential for achieving optimal sample loading and recovery. Application of RAM technology on the microsphere''s outer surface reduces the adsorption of protein colloids. Additionally, employing molecular imprinting technology optimizes the inner surface modification of microspheres, thereby enhancing the enrichment capacity for catecholamines and vitamin K.

磁核的包裹过程对于防止氧化和磁化丧失至关重要。并且要确保微球介孔孔径均匀和高比表面积,才能得到好的载样量以及回收率。球的外表面应用RAM技术可减少蛋白胶体的吸附。此外,采用分子印迹技术优化了微球的内表面修饰,从而增强了对儿茶酚胺和维生素K的富集能力。

Figure 4. Bonnacats magnetic beads remain stable in acidic conditions without metal leaching

图4. Bonnacats磁珠在酸性条件下保持稳定,不会释放金属

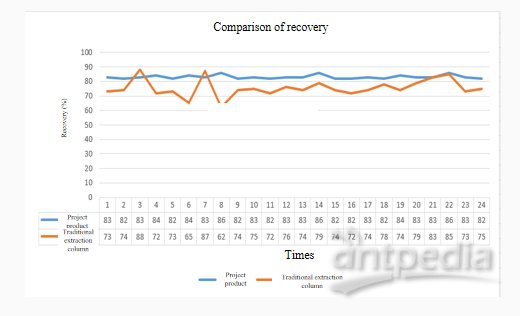

Figure 5. Comparison of recovery rates to conventional column extraction

图5. 与传统柱式萃取方法的回收率比较

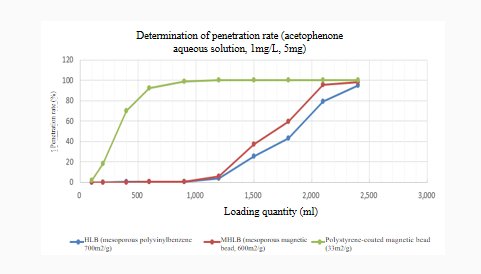

Figure 6. Comparison of sample loading to existing market products

图6. 与现有市场产品的上样量比较

Table 1. Comparison between m-SPE and conventional SPE techniques

表1. 磁固相萃取(m-SPE)与传统固相萃取(SPE)技术比较

Method

方法

Auto M32 system was used for the extraction and purification of catecholamine targets from plasma samples containing six endogenous targets. Specifically, the corresponding solvent was transferred into a designated 96-well plate. Subsequently, the Auto M32 Fully Automatic Sample Pretreatment System conducted magnetic extraction of the samples. Upon completion of the extraction process, the eluent obtained was injected into an LC-MS/MS system for subsequent analysis and testing.

Auto M32用于从血浆中提取和纯化儿茶酚胺。将相应的溶剂转移到指定的96孔板中,然后Auto M32全自动样品前处理系统对样品进行磁性萃取。提取完成后,将洗脱液注入LC-MS/MS进行检测。

Table 2. Operating procedures of Auto M32 m-SPE pretreatment system

表2. Auto M32磁固相萃取前处理系统的操作步骤

Result

结果

Recovery Rates

回收率及平行性

Table 3 shows the results obtained from plasma samples collected from a healthy individual. Following the addition of six catecholamine internal standards, the observed recovery rates ranged from 95.2% to 116%, with corresponding relative standard deviations ranging between 1.4% and 9.3%. The test was performed in duplicate parallel runs.

如下表所示,取某正常人血浆,添加六种儿茶酚胺类目标物,两次平行处理。所得回收率95.2-116%,相对标准偏差1.4-9.3%。该测试进行了重复的平行实验。

Table 3. Recovery rates and relative standard deviations of 6 catecholamine targets in plasma samples

表3. 血浆样品中6种儿茶酚胺目标的回收率和相对标准偏差

Reproducibility of Continuous Internal Standard Peak Area

As presented in Table 4, utilizing standard samples with a plasma concentration of 0.2ng/mL (3-MT, 0.02ng/mL) as a representative case, the relative standard deviation of the internal standard peak area ranged from 4.4% to 9.7%. The test was performed in six parallel runs.

连续内标峰面积重现性

如下表所示,取血浆浓度为0.2ng/mL(3-MT,0.02ng/mL)标准样品平行处理六次,内标峰面积相对标准偏差4.4-9.7%。该测试进行了六次平行实验。

Table 4. Peak areas of 6 catecholamine targets in 6 parallel runs

表4. 在6次平行实验中6种儿茶酚胺目标物的峰面积

Standard Curve

Standard Curve Linearity and Accuracy of Six Catecholamines, as Shown in Table 5.

标准曲线

如下表所示,六种儿茶酚胺类标准曲线线性及其准确度。

Table 5. Standard curves of 6 catecholamine targets

表5. 6种儿茶酚胺目标的标准曲线

Conclusion

结论

The advancement of mesoporous paramagnetic extraction materials and the automated moving-bed extraction method represents a pivotal development. It not only ensures the consistency of trace substance extraction and precise detection of biological samples but also markedly enhances efficiency and extraction speed through complete automation. This breakthrough in sample preparation automation signifies a significant stride forward for the application of LC-MS in clinical testing.

介孔顺磁萃取材料的优势以及自动移动床萃取方法代表了一个关键性的进展。它不仅确保了微量物质提取的一致性和生物样品检测的精确性,而且通过完全自动化显著提高了效率和提取速度。样品制备自动化这一技术的突破,标志着LC-MS在临床测试中的应用向前迈出了重要一步。

苏州艾捷博雅欢迎您莅临

ASMS展位No. 238,Poster编号WP118

·END·

06-27 小 M

有投必奖 | 大家都用 MCE 产品做了啥? (感染领域)06-27 小 M

科研助攻 | 一文讲清:如何破解 PPI 靶点成药难题06-27 小 M

干货分享 | 谈谈天然产物的改构策略06-27 小 M

玉研口鼻暴露系统 | 精准、可控、高通量的动物肺部疾病造模工具,助力创新药物研发06-26 玉研仪器

屹路同行 悦启新程06-26 屹尧科技

徕卡精准空间生物学解决方案 第四弹06-26 童昕、南希

【直播预告】第一届大湾区生物电镜制样讲习班06-26 徕卡显微系统

徕卡常规显微镜历经严苛的ISO9022标准测试06-26 徕卡显微系统

Viventis LS2 Live 光片显微镜发布会06-26 徕卡显微系统

前沿应用 | 经皮无创血糖检测中葡萄糖拉曼峰直接观测06-26 鉴知技术

推陈出新!通微公司携新品亮相本届CPHI06-26 Unimicro

远离氟污染!开启无氟接触前处理技术新篇章06-26

浑然一体的ChemiSEM技术:集成式扫描电镜成像与 X 射线能谱解决方案06-26

荧光计 VS 分光光度计,倒底怎么选?06-25

最新研究解读:临床基因组测序的普及正助力缩小罕见病诊疗地区间差距06-25

喜讯!奥谱天成·集团及联合创始人刘鸿飞博士荣获新称号06-25

欧盟GMP附录1与污染控制策略——更快、更便捷的过程监测创新技术06-25 Sievers分析仪

喜报!通微公司成为国家级博士后工作站06-25 Unimicro

自旋极化子直接观测!无液氦磁体恒温器助力一篇Nature Physics06-25 Dr. Shen